技術概念 / Concept

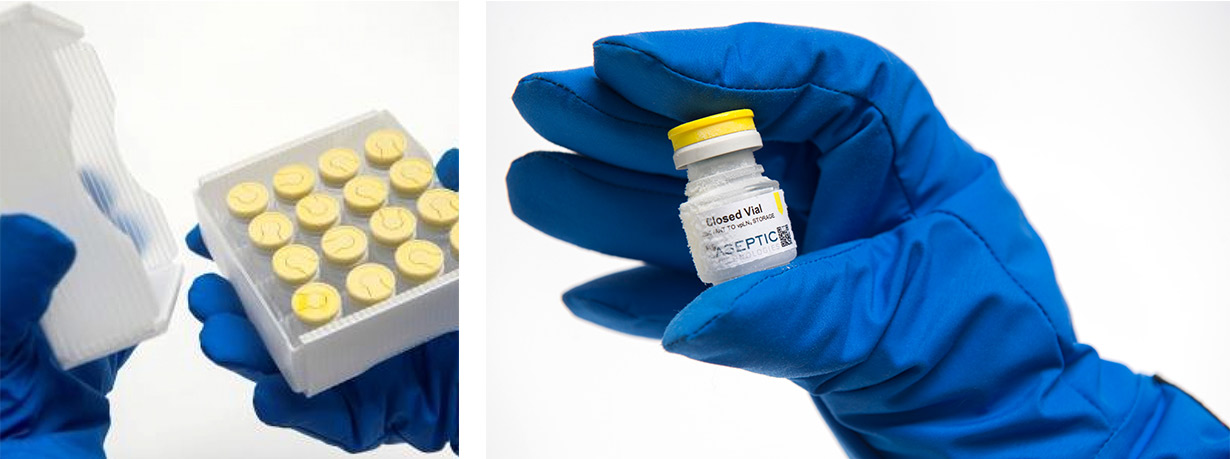

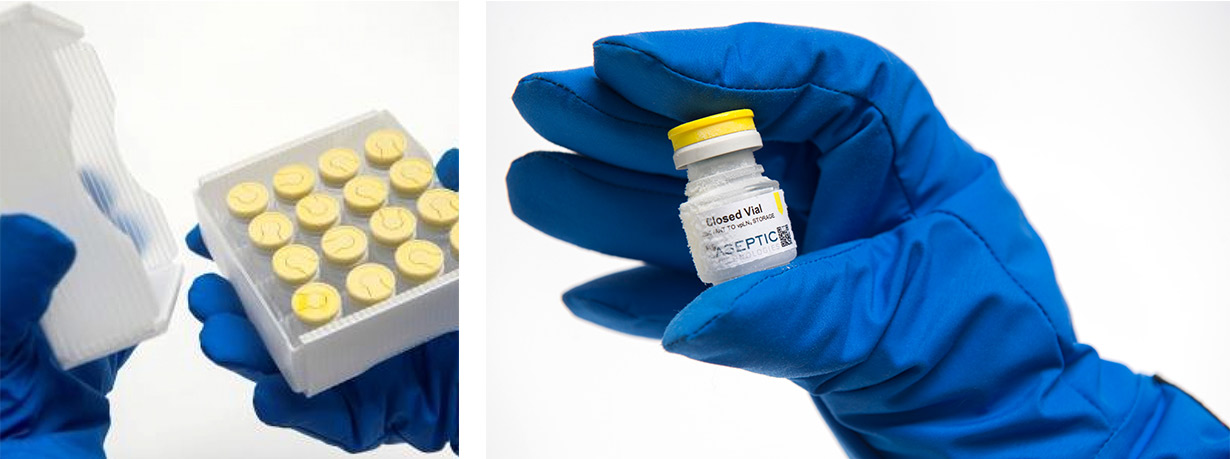

The AT-Closed Vial® Technology is based on the concept of the ready-to-fill Closed Vial, whereby polymer vials are provided:

-clean (molded in ISO 5 clean room);

-closed (stopper in place and secured);

-sterilized (gamma-irradiated).

應用領域 / Fields of use

Biological

Biological

-Vaccines

-mAbs

-RNA/DNA-based products

Low leachable profile, twice less particles then in glass vial. Potent

Potent

-Radiopharmaceuticals

-mAbs

-Nanomedicines

Unbreakable container, always closed to avoid contamination. Cryostored

Cryostored

-Cell therapy

-Gene therapy

-Other low T° storage products

Container Closure Integrity even in liquid nitrogen.

步驟說明 / Process

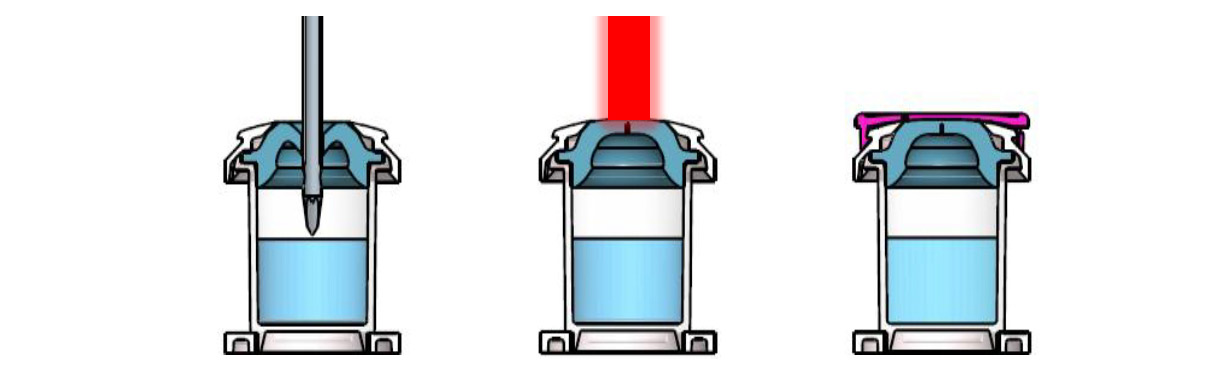

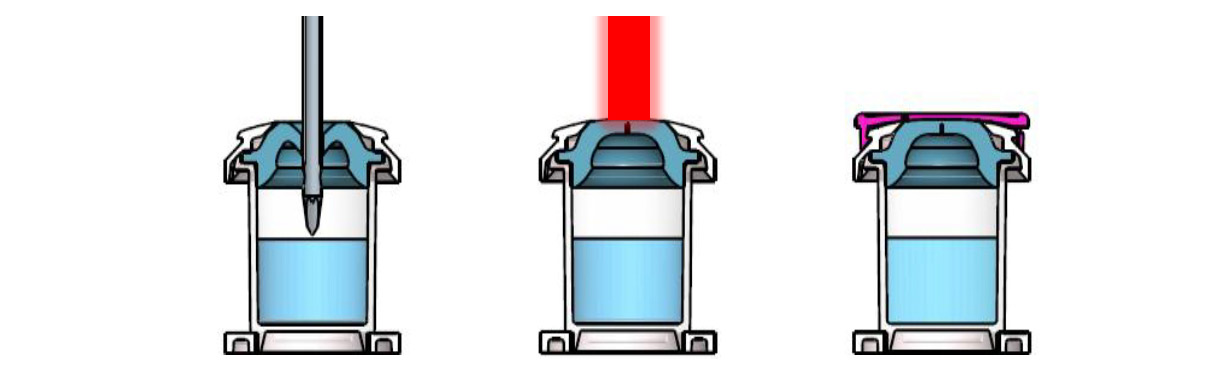

The overall filling process of the ready-to-fill AT-Closed Vials® is made of very few steps:

1.Filling of the vial with a needle puncturing the elastomeric stopper.

2.Immediate laser re-sealing to restore the closure integrity of the filled vial.

3.Capping with a tight snap-fit cap protecting the piercing area.

材質 / Materials

Materials selected for the product contact parts meet USP and EP requirements for pharmaceutical primary container:

-COC (Cyclo-Olefin Co-polymer) for vial body, known for shock-resistance, barrier properties and transparency;

-TPE (Thermo Plastic Elastomer) for stopper, a proprietary material allowing specific processing;

both having excellent leachable profile.

The fully automated vial manufacturing process ensures clean conditions: vial and stopper are molded in Grade A/ISO 5 and immediately assembled by robots, minimizing particle content compared to other types of primary containers.

AT-Closed Vials® are then packed and sterilized by gamma irradiation, being supplied as Ready-to-Fill containers.

.jpg)

.jpg)