Unique aseptic design

The Sterivalve® range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

The Sterivalve® has a unique patented design using a configuration in which the valve diaphragm is clamped between the valve body and the actuator. All moving parts in the actuator are completely isolated from contact with the process fluid and tools are not required for disassembly or service for most valve sizes. All materials of construction conform to FDA and GMP requirements. Both the valve housing and the piping connections are self draining without dead-legs. This will result in a reduction in hold up volume of the complete piping system.

The Sterivalve® has been used and validated in a wide range of clean and sterile processes worldwide. The design of the housing, which features a low residual internal volume, ensures optimal velocity of cleaning agents during the CIP process. The self-draining and open internal structure of the valve housing also ensure safe and reproducible CIP and SIP performance; thus avoiding the risk of bacterial and endotoxin contamination, or undesirable temperature gradients. It is also possible to clean and sterilize both the inlet and outlet pathways of the Sterivalve in the closed position if required.

The manufacturing of Sterivalve® is quality assured and certified in accordance with ISO 9001 and benefits from our extensive experience within the pharmaceutical industry.

Shut off valves (SOV) Valve for piping system

The Sterivalve® Shut off valves (SOV) range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

- Shut off valves have a 90° angle from inlet to outlet and can easily be welded or clamped in. The valve is drainable and CIP/SIP (Clean In Place/Steam in Place) capable.

- Aseptic patented design.

- Deadleg free design assures full microbiological control of the valve system, preventing contamination by bacteria or endotoxine.

|

Valve housing: |

316L Other material on request |

|

|

Surface Finish: |

Ra 0.38 μm, electropolished. |

|

|

Valve size: |

0,5″ to 3″ |

|

|

Outlet connections: |

But weld (BW), TC- ends |

|

Standards: |

ASTM, other standards on request |

|

|

Option: |

Steam port, CIP/SIP satellite valve |

|

|

Actuator: |

Manual or pneumatic, Stainless steel or plastic Inductive or microswitch actuator indicators Option Atex indicators |

|

|

Diaphragms: |

Silicone, EPDM and PTFE, USP Class VI |

Bottom outlet valve (BOV) Tank outlet valve

The BOV range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

- Steridose bottom outlet valve (BOV) is drainable and CIP/SIP (Clean in Place/Steam in Place) capable. The valve body is flush welded to the tank bottom thereby becoming an integral part of it.

- BOV is deadleg free and has self draining and the internal contour of the valve has no dead spaces, hence the valve is very suitable in combination with mixers if the medium is sediment.

- Aseptic patented design.

- Deadleg free design assures full microbiological control of the valve system, preventing contamination by bacteria or endotoxine.

|

Valve housing: |

316L Other material on request |

|

|

Surface Finish: |

Ra 0.38 μm, electropolished. |

|

|

Valve size: |

0,5″ to 3″ |

|

|

Outlet connections: |

But weld (BW), TC- ends |

|

|

Standards: |

ASTM, other standards on request |

|

|

Option: |

Steam port, CIP/SIP satellite valve |

|

|

Actuator: |

Manual or pneumatic, Stainless steel or plastic Inductive or microswitch actuator indicators Option Atex indicators |

|

|

Diaphragms: |

Silicone, EPDM and PTFE, USP Class VI |

Flow Through Valves (FT) Valve for piping system

The Sterivalve® Flow through valve (FT) range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the bes

- Steridose flow through valve (FT) is drainable and CIP/SIP (Clean in Place/Steam in Place) capable. Proven performance in FDA approved plants and In accordance with GMP regulations. The valve is often welded or clamped into ring mains enabling the working medium to be taken or fed deadlegfree at an optimal point.

- Aseptic patented design.

- Deadleg free design assures full microbiological control of the valve system, preventing contamination by bacteria or endotoxine.

|

Valve housing: |

316L Other material on request |

|

|

Surface Finish: |

Ra 0.38 μm, electropolished. |

|

|

Valve size: |

0,5″ to 3″ |

|

|

Outlet connections: |

Steam port, CIP/SIP satellite valve |

|

Standards: |

ASTM, other standards on request |

|

|

Option: |

Manual or pneumatic, Stainless steel or plastic |

|

|

Actuator: |

Inductive or microswitch actuator indicators Option Atex indicators |

|

|

Diaphragms: |

Silicone, EPDM and PTFE, USP Class VI |

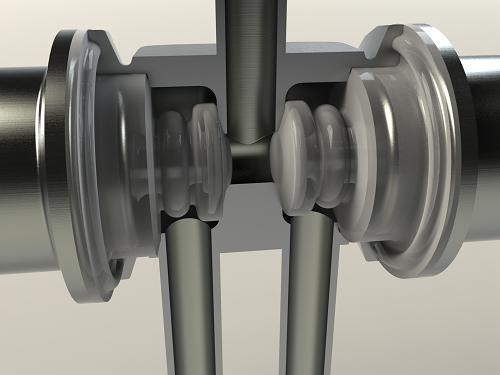

Divert valve (DIV)

The DIV range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

Steridose Divert Valve (DIV) can be used to divert flow or as a mixing valve. This patented design will drain in either the horizontal or vertical position.The flow pattern on the closed side of the valve will allow for a continuous flow to the open side providing zero dead leg. The inlet flow passage with the divided flow prevents abrupt directional change and fluid impact that can minimize cell deterioration.

Steridose Divert Valves (DIV) are available in two-way configurations and can be supplied with pneumatic or manual actuators. The valves housing is machined from solid 316L stainless.

Other alloys such as Hastelloy or AL6XN can be provided upon request.

Steridose Divert Valves (DIV) are supplied with a clamp or weld end connection in sizes ranging from 1/2″ through 3″ with EPDM/ SILICONE/ PTFE diaphragms in USP Class VI/ FDA compliance.

- No tool required for assembling and maintenance.

- Design eliminates dead leg inherent in typical mixing or diverting applications.

- Significantly reduces overall spacing requirements.

Take off valve (TOV)

Point of use valve, T-zero dead leg valve, True zero dead leg sampling valve, Pipe outlet valve

The TOV Range provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

Features

The Steridose TOV is totally dead leg free and is specifically designed as a sampling valve for piping systems, mostly WFI and PW loops. The radial diaphragm seats flush to the inside of the main pipe. Many flat diaphragm valves are being used in this type of application. However, they cannot be sealed directly into the pipe. This makes our TOV a much better choice in terms of cleanability.

|

Valve housing: |

316L Other material on request |

|

|

Surface Finish: |

Ra 0.38 μm, electropolished. |

|

|

Valve size: |

0,5″ to 3″ |

|

|

Outlet connections: |

But weld (BW), TC- ends |

|

|

Standards: |

ASTM, other standards on request |

|

|

Option: |

Steam port, CIP/SIP satellite valve |

|

|

Actuator: |

Manual or pneumatic, Stainless steel or plastic Inductive or microswitch actuator indicators Option Atex indicators |

|

|

Diaphragms: |

Silicone, EPDM and PTFE, USP Class VI |

Sampling valve: welded or TC connected flush to the tank

The Steridose Sampling valve provides high performance flow control for pharmaceutical and biopharmaceutical liquid processes. Using a hydrodynamically optimized design, the Sterivalve® combines the best features of a seat valve with the inherent cleanability of a flat diaphragm valve. This combination of features ensures that the Sterivalve® offers the unique combination of low flow resistance together with a proven hygienic design.

- Steridose Sampling valve is drainable and CIP/SIP (Clean In Place / Steam In Place) capable. The valve body is flush welded or TC connectable to the tank thereby becoming an integral part of it.

- Steridose sampling valve is deadleg free and the internal contour of the valve has no dead spaces.

- Aseptic patented design of clamped double membrane sealing.

- Deadleg free design ensures microbiological control of the valve system, preventing contamination by bacteria or endotoxine.